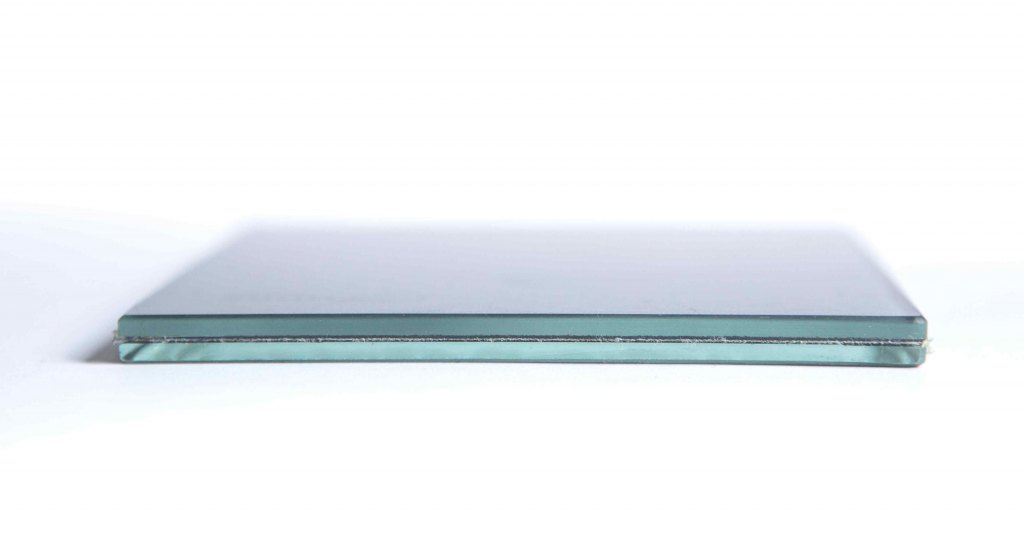

Bonding two panes of glass with an interlayer produces laminated glass, a catch-all term to cover the various combinations of glass and interlayer. Because the interlayer holds the glass even when broken, laminated glass is typically used where security is a priority, as well as in safety applications like overhead and walk-on glazing.

By far the most common interlayer is polyvinyl butyral (PVB). Ethylene-vinyl acetate (EVA) is also popular; other interlayer materials include cast-in resins, polyurethanes and ionoplast materials.

Where transparent plastic materials, like PVB and EVA, are used as the interlayer, the bond is achieved through the application of heat and pressure in a controlled environment; however, plastic interlayers make cutting difficult. Resin is a more versatile adhesive and allows for the production of curved laminates.

Demanding performance specifications are driving the development of interlayer solutions, some of which fail to offer adequate levels of adhesion.

Manufacturers of proprietary interlayers, such as ionomer-based ionoplast, claim improved performance for especially demanding applications. PVB, however, remains the popular option.

As a hygroscopic material, PVB absorbs moisture and can turn cloudy as a result. Poor storage of PVB can lead to it having an increased moisture content prior to use, while good edge sealing of the glazed unit stops moisture getting to the interlayer; either can risk delamination. Delamination may also occur if distortion in the two glass panes is poorly matched and introduces stresses in the interlayer.

What is laminated glass?

It is important to understand when specifying glass for use in rooflight systems, that the combination of interlayer and glass panes that make up the complete section is critical in achieving your desired performance.

Laminated glass is two or more sheets of glass bonded together with a plastic interlayer, this interlayer holds the glass together and will be retained in the frame in the instance that either or both of the glass sheets should break. It is therefore a safety glass and can be used in overhead glazing.

Annealed glass is not as strong as toughened glass and is susceptible to thermal fracture. This is caused when there is a significant temperature difference within the same piece of glass and is likely to occur where adjacent structure or trees, for instance, could cast a shadow across the glass with part of it in sunshine and part in shade.

It can also be caused by other finishes being located close to the underside of the glass where heat coming in through the glass is reflected back to the underside. This can be caused by wide upstands or the fitting of blinds in close proximity. A rooflight with an annealed laminated inner pane would be classified as non-fragile.

What is heat strengthened laminated glass?

Heat strengthened laminated glass is considered the most suitable option for most general use glass rooflights. It is similar to annealed laminated glass, except the sheets of glass that are laminated together have been heat strengthened. This glass is twice the strength of annealed glass and is resistant to thermal heat stress cracking and does not suffer from the very small risk of Nickel Sulphide inclusions that may affect some toughened glass.

Heat strengthened laminated glass is a more expensive option, but it offers one of the broadest specifications for overhead glazing, as it is considered a safety glass which will be retained in the frame if broken and is not susceptible to thermal heat stress cracking. A rooflight with a heat strengthened laminated inner pane would be classified as non-fragile.

Toughened and heat soak tested laminated inner pane

Toughened laminated glass is similar to annealed laminated glass except the sheets of glass that are laminated together have been toughened and heat soak tested.

This glass has all the benefits of toughened glass but without the risk of pieces of glass falling from the roof light if one or both of the sheets of glass in the laminate should break. It is not susceptible to thermal heat stress cracking. A rooflight with a toughened laminated inner pane would be classified as non-fragile.

For more information about the benefits for both toughened and heat-strengthened glass, download our guide to specifying glass in rooflights whitepaper.