The rise in home owners extending their properties has increased alongside a growing demand for suitable rooflights for flat roofs.

Therefore, it is important to recognise that installing a rooflight onto a flat roof is not simply a case of installing a section of glass over an opening.

This is of course a quick and easy approach that may provide a solution for a while, but in time common issues will develop that can cause untold damage to your roof and building internals. Such issues can be avoided if you specify the right product for the job.

The correct or minimum pitch for flat roof fixed rooflights

Although rooflights for flat roofs are now much more readily available, product manufacturers often hear similar questions as to how they should be installed, one of the most common being ‘what pitch do I install the unit at?’

There is no single answer to this question due to product ranges being quite diverse. However there is still a methodology behind it, which this post will discuss in relation to the most straightforward fixed rooflights.

For planning reasons and aesthetics, customers often ask if the rooflights can be installed onto a flat roof.

It is recommended that regardless of overall dimensions, a minimum 3 degree fall is sufficient to ensure that water will drain off the surface of the glass and avoid ponding, a process in which puddles of water on the glass surface evaporate and leave unsightly dirt and staining on the glass.

With a minimum 3 degree fall, individual droplets of water will still stay on the glass as they would on vertical glazing, but larger pools of water will not form.

In all glazing there is a degree of flex or ‘deflection’ that is particularly apparent on overhead glazing. A combination of wind load, snow load and the physical self-weight of the glass all contribute to the amount of deflection that is apparent. The glass rooflight specification should be calculated so that the maximum amount of deflection under the worst case loading and on the largest pane sizes does not exceed 25mm.

Without the pitch, any deflection in the glass will increase the severity of water ponding so installing the roof light at a minimum 3 degrees is the recommended method for avoiding this problem .

Increasing roof light pitch to 5 degrees

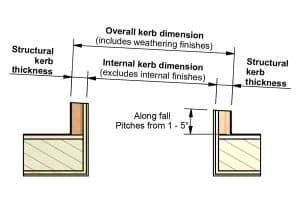

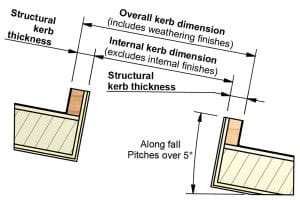

For more efficient results and improved drainage, increasing this to 5 degrees, as shown in the following diagram, can be beneficial; the pitch is constructed by building the required slope into the upstand itself.

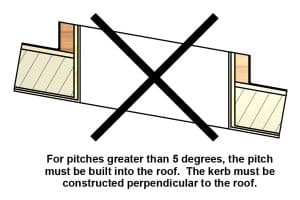

For pitches greater than 5 degrees, the pitch must be built into the roof with the kerb constructed perpendicular to the roof as illustrated below, otherwise the down leg of the framework may foul the external face of the kerb. This could result in a poor fit that means the rooflight is not properly supported.

Specification considerations should also be given to the orientation of the rooflight. For example, if you have specified a unit 5 mt width x 1 mt span, it would be wise to build the pitch into the span dimension; the differential between kerb heights on opposing sides is reduced and water has less distance to travel when running off the unit.

Specifying Walk on Rooflights

The only real exception to the 3 degree rule is where walk on specification glass is going to be used; obviously the glass needs to be as level as possible for its chosen application.

For walk on use, it is recommended to build a 1 degree fall wherever possible to allow some run off. The risk of ponding is marginally greater but because walk on glass is so much thicker in order to carry the design floor loadings, the deflections relative to pane size will be far less than with standard double or triple glazing. In addition, since the unit is accessible, the glass can be cleaned far more easily so that water ponding is not so much of an issue.

Please note that requirements may vary depending on your chosen manufacturer. Always check that the specification meets your flat roof design.

It is also critical to consider your supplier when specifying rooflights for flat roof applications. Due to the minimal pitch used it is important to look in detail at the product and ensure that there is no external capping around the edge of the unit, which could trap moisture and dirt, leaving an unsightly mess.

Glazing Vision’s Flushglaze range pioneered the development of ‘flush’ fitting glazing within its framework, resulting in a perimeter edge free of capping that allows water to run off the unit much more effectively, leaving your rooflight cleaner for longer.

For further advice and information regarding kerb pitches, the following documents are available for download:

s0009-kerb-dimensioning-information

402ASS051 – Flushglaze kerb detail