Posted on September 25, 2023 in Blog, News, Sustainability

At Glazing Vision, our commitment to innovation and sustainability extends beyond precision-engineered architectural glass rooflights.

Why plastic waste management is important to Glazing Vision

Why is plastic waste such a big problem?

The issue of plastic waste looms large, touching virtually every aspect of our daily lives. From food packaging to clothing, electronics to furniture, plastic is omnipresent. Its durability is both a boon and a curse, as it often refuses to biodegrade, lingering in landfills for decades to potentially millions of years. Tragically, only a meager 9% of all plastic ever produced has been recycled, with the majority either incinerated or carelessly discarded, ultimately finding its way into landfills and the environment.

In 2019 more than 130 million tonnes of single-use plastic ended up as waste with around 8 million tonnes finding their way into the oceans; and this figure continues to grow. A study in 2021 revealed that single-use plastic items specific to take-out containers and beverages dominate global litter, including that of our oceans. A further survey in July 2023 showed just 12 companies were responsible for 70% of branded litter found on UK coastlines, canal paths and streets.

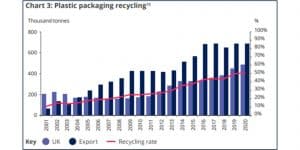

Although UK and EU legislation for single-use plastics has changed considerably and technological advances have been made in recent years, the ability to recycle plastics remains a constant challenge. Some single-use plastics cannot currently be recycled using existing technologies.

Although UK and EU legislation for single-use plastics has changed considerably and technological advances have been made in recent years, the ability to recycle plastics remains a constant challenge. Some single-use plastics cannot currently be recycled using existing technologies.

There is also still a need for improved and consistent labelling, information on product recyclability and improved end-of-life disposal methods. For example, a plastic deposit return scheme due to commence in August 2023, now delayed until 2025, has the aim of ensuring 85% fewer drinks containers are discarded as litter within three years of launch.

The impact on our oceans is particularly dire. With their vast expanses and deep depths, oceans act as global pollution sinks. Lost cargo from ships, abandoned fishing gear like ghost nets and lines, and even polystyrene foam from marine aquaculture contribute to this plastic menace. The consequences are profound, with marine ecosystems suffering as plastic persists for centuries, wreaking havoc on aquatic life. This urgent issue demands our collective attention and action to stem the tide of plastic waste into our beloved oceans.

The importance of ISO 14001

In the ever-evolving landscape of industry and architecture, ISO 14001 emerges as a pivotal force championing sustainability. This globally recognised environmental management standard is more than a mere compliance requirement – it’s a strategic imperative for manufacturing companies. By adopting ISO 14001, these firms begin to consider environmental responsibility, cutting-edge efficiency, and enhanced reputation. This standard allows them to methodically identify and address environmental challenges, resulting in reduced energy consumption, minimised waste production, and a tangible reduction in greenhouse gas emissions.

In our ongoing commitment to environmental sustainability, we’ve achieved significant reductions in our energy consumption. Our efforts in resulted in a remarkable 40.75-tonne reduction in greenhouse gas emissions for 2023 when compared to our baseline year data from 2021. This achievement signifies a substantial reduction in energy consumption across our operations, demonstrating our dedication to minimising our environmental impact. Furthermore, we’ve implemented energy-efficient lighting solutions throughout our facilities, such as replacing conventional bulbs with energy-efficient LED equivalents. These upgrades not only enhance visibility but also contribute to substantial energy cost savings, exemplifying our commitment to both environmental responsibility and cost-efficiency.

We’ve remained proactive in identifying opportunities for energy savings and sustainability improvements. Our continuous improvement initiatives, like specialised skip collections for green waste and the replacement of sodium lights with energy-efficient LED lights in our Goods Yard, have contributed to enhanced energy efficiency. These efforts underscore our commitment to reducing our carbon footprint and promoting responsible energy management. As we move forward, we remain dedicated to exploring new avenues for energy conservation and continually improving our environmental performance.

For architects, ISO 14001 isn’t just a technicality; it’s a guide to responsible choices in manufacturing partnerships. Aligning with ISO 14001-certified manufacturers signifies a shared commitment to sustainability. Such collaborations pave the way for architectural marvels that not only meet today’s stringent environmental standards but also contribute to a greener, more resilient future. These partnerships ensure the creation of eco-conscious buildings that seamlessly blend into their surroundings while delivering great quality and performance.

What is Glazing Vision doing already to tackle this problem?

As a manufacturer with ISO 14001 accreditation, we deeply acknowledge our pivotal role in shaping a greener, more eco-conscious world, and this ethos runs through the very fabric of our business.

Nestled on the outskirts of town, we share a unique kinship with the Frenze Beck Nature Reserve, where we harmoniously coexist with the environment. Here, we tread lightly, using weedkilling chemicals sparingly and nurturing local wildlife habitats, even witnessing the beauty of bee orchids in our midst.

Our commitment to uncompromising quality and environmental management is vividly apparent through the external audits we undergo, conducted by esteemed bodies such as the British Standards Institute, BRE Global, BBA, and IFC certification.

At Glazing Vision, our sustainability vision is as clear. We aspire to be not just carbon-neutral but carbon-negative, and we have made it our mission to infuse sustainability into every facet of our operations, from the sourcing of materials to the meticulous packaging of our products.

Our aim is to empower our customers to embrace the natural beauty of light, the efficiency of energy, and the joys of eco-friendly living, all while reducing their energy consumption.

However, our commitment to responsible practices extends beyond environmental realms. We actively engage with charitable organisations like CRASH and champion employee-led fundraisers for causes that resonate deeply with our team. Youth development and fair wages are not just aspirations; they are principles we hold dear. As an ISO 9001 certified company, we continually seek opportunities for improvement and innovation.

At Glazing Vision, sustainability isn’t just a strategy – it’s our way of life. We view ISO 14001 adherence not as a mere compliance requirement, but as a profound covenant for a brighter, more sustainable future, one that benefits us all.

“In manufacturing, environmental repercussions are present at every stage, even within defects, rejections, rework, or replacements. The ISO 14001 management system helps us to see that impact and the benefits that can be achieved from ‘Right First Time’ manufacturing.” – Michelle Rolph, QSHE Manager at Glazing Vision.

The Future

In the realm of manufacturing, it’s clear that substantial change on a global scale hinge upon collective action by companies of all sizes. Nevertheless, it’s worth remembering that even small individual efforts can ripple into significant impacts, especially within our local communities.

The necessity for change becomes increasingly evident with each passing day, as news reports continue to shed light on the ongoing environmental crises unfolding worldwide. In recognition of the critical importance of reducing plastic waste, the United Kingdom has set a goal to eliminate plastic pollution by the year 2040.

To drive this change, consumers hold a considerable lever of influence, primarily by reducing their reliance on single-use plastics. The transition away from such plastics is facilitated by the availability of more sustainable materials like bioplastics, hemp-based composites, and recycled resources. Furthermore, the ever-evolving landscape of research and development continually presents opportunities for the emergence of new, environmentally friendly materials and innovative production methods.

In this intricate web of transformation, it’s vital to acknowledge that each conscientious choice, no matter how modest, contributes to a world that is more aligned.

We’ve taken significant steps in our commitment to sustainability. We’ve eliminated single-use plastics, such as drinking straws, and replaced them with reusable drink containers. Plastic cutlery and crockery have been replaced with sustainable alternatives. Coffee pods are now being recycled, and our overall recycling efforts have been ramped up, including the recycling of PVC offcuts generated during manufacturing. These achievements are a testament to the unwavering dedication of our staff.

Even small changes have yielded remarkable results. For example, we conducted a review that led to a reduction in the number of plastic packers included in our installation kits, resulting in the elimination of 160,000 individual pieces annually.

Furthermore, we’ve conducted a thorough plastics audit, the findings of which are guiding our strategies for the next phase of reduction. This phase involves collaborating with our suppliers to either eliminate or reduce plastic packaging, all while maintaining our commitment to product quality.

“I aspire to lead a company that doesn’t merely adhere to existing standards, but rather pioneers new ones! This is why my foremost priority is to minimise our carbon footprint and promote awareness about plastic.

My deep affection for the ocean fills me with sadness as I witness how human actions are wreaking havoc on marine life through reckless plastic disposal. I hope anyone reading this will reassess their plastic consumption and join us in spreading awareness about the devastating impact of plastics on our avian and aquatic ecosystems, as well as the potential harm to humans through our food chain.” – Jon Shooter, Managing Director at Glazing Vision.

Want to see some case studies we’ve done with the goal of being more eco-conscious? Check these out: